Features plasma cutting machine

1. The rack is fully welded, solid and reasonable, simple and durable.

2. Plasma cutting machine Y axis adopts double moters with double drivers. XYZ axis round raill, moving smoothly, with high accuracy. (Option: squar raill)

3. Independent research the water cooling system to ensure that the materials smooth deformation of incision.

4. High configuration. Automatic THC/ARC, stable performance, arc success rate of 99% or more.

5. Support Fastcam software such as the standard G code path generated file can also be read by software conversion software such ad AUTOCAD generated DXF formats. U disk exchange control system processing files, easy to operate

Parametrii

X Y Drive System: Rack and Pinion Drive, Hiwin Linear Rails

Z Drive System: Ball Screw, Hiwin Linear Rails

Drive Mode: Stepper or Servo

Tensiune de lucru: AC380V / 50Hz

Positioning Accuracy: 0.03/300mm

Mod de conectare: interfață USB

Plasma Power Source: Hypertherm, Huayuan

Grosime de tăiere: 1-50 mm

Plasma Table: Knief Table Surface

Sistem de control: Porniți sistemul de control

Pachet de transport: Pachet de placaj

Specification: Depend On plasma type

HS Code: 8456901000

| Zonă de muncă | 1300x2500mm/1500*3000mm/2000x3000mm |

| Material de lucru | Iron, steel, aluminum, sheets, galvanized sheets, titanium plates |

| Grosimea tăierii | 0.5-40mm |

| Viteza de taiere | 0-8000mm / min |

| Sistem de control | Beijing Start control system(The updated controller) |

| Control software | Fastcam |

| Sistem de antrenare | Stepper /Servo |

| Tensiune de intrare | 220V / 380V - 50HZ |

| Putere plasmatică | 63A(100/120/160/200A for option) |

| Files transfer | USB interface |

| Arc | Untouched arc striking |

| File format | G-code |

| Plasma source | Huayuan or Hypertherm(depend on you) |

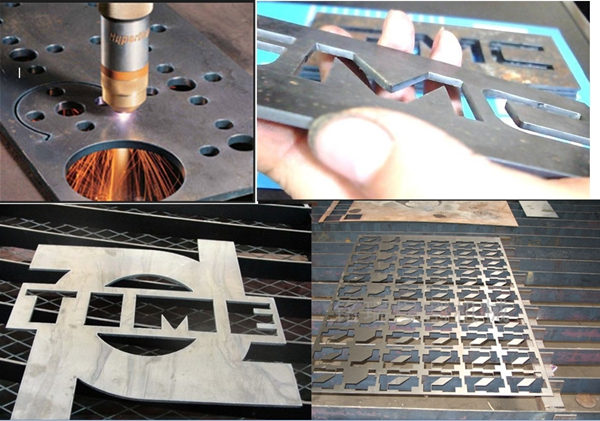

Application and Sample

Mașină de tăiat cu plasmă CNC is automatic and high efficiency cutting equipment. Mașină de tăiat cu plasmă CNC is widely used in all kinds of carbon materials cutting, mild steel materials cutting and nonferrous metal precision sheet metal cutting.

Package and Shipping

1. Lead time: Within 7-12 working days after receiving payment.

2. Packing: All machines are packed with standard inner plastic wrap and outer plywood case.

The inner package would be helping to tight all the small parts in the package. And the plywood is firm enough to protect the cnc machine during shipping.

After-sales Services

1. 2 year guarantee for main machine (People damaged are charged).

2. Full technical support\ by e-mail, call and video

3. Lifelong maintenance and spare parts supply.

4. Free design of fixtures as customers required.

5. Free training installation and operation for the staffs.