1.Descriere

Mașină de tăiat cu laser integrează tehnologia optică, mecanică și electrică într-o singură mașină, care adoptă tehnologia laser, tehnologia de control computerizat și sistemul de putere laser CNC de înaltă performanță (control numeric pe computer). Mașina de tăiat cu laser este capabilă să prelucreze toate tipurile de tablă cu viteză și eficiență ridicate.

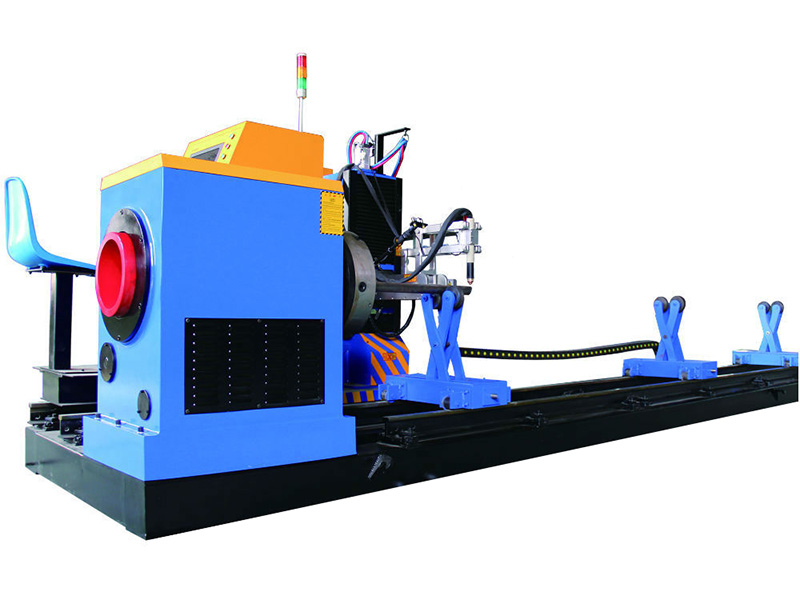

Mașină de tăiat cu laser ACCURL3015IIIWJAT-2000 se aplică atât la tăierea tablei metalice, cât și la tăierea țevilor. Dimensiunea maximă a foii pe care o poate tăia este aceea de 3000mm×1500mm, dimensiunea maximă a țevilor este aceea de grosime 3mm, lungime 6000mm, țeavă rotundă Ф25-Ф160mm, țeavă pătrată 25mmx25mm-100mmx100mm (diagonală 30mm-160mm). Produsele vor avea margine netedă, cu finisaj de înaltă calitate a suprafeței, lățime mică a tăieturii și efect de căldură redus. Mașina este potrivită în special pentru tăierea tablei sau țevilor metalice.

2.Componentele echipamentelor

1) Laser

Laser cu fibră IPG-2000W

(1)Putere de ieșire laser 2000W

(2)Lungime de undă laser 1070nm

(3) Modularea energiei de ieșire 10%-100%

(4)Putere de intrare <8KW

(5)Temperatura de lucru 15-35ºC

2) Cap de tăiere cu laser cu fibră optică

Capul de tăiere cu laser adoptă tehnologia germană, echipat cu conector de ieșire din fibră QBH, lentilă optică specială, metodă de reglare precisă a focalizării sigilată și traductor de capacitate rapidă cu spațiu de tăiere minim de 0,2 mm, ceea ce ar putea crește viteza de tăiere și ar putea reduce consumul de gaz.

3) Mașină unealtă

Mașina adoptă o structură portal, grinda și patul sunt într-un singur proces cu înaltă precizie, rigiditate bună, funcționare lină.

Baza mașinii: Baza folosește tubul sudat de înaltă calitate și structura cadrului, prin sudare profesională, tratament secundar de îmbătrânire, mașină de frezat cu portal mare precisă, prelucrare de precizie, aceste modele și metode de procesare asigură rezistența la șocuri excelentă, rigiditatea ridicată și stabilitatea mașinii. .

Sistem de desgaraj: Colectorul de blanking este dispus in partea inferioara a patului, care poate indeparta deseurile si colecta piese mici in timpul taierii.

Sistem de îndepărtare a prafului: Platforma de lucru folosește designul de colectare a prafului pentru a îndepărta praful și gazele de eșapament.

Mese de lucru cu schimb automat: Două mese de lucru automate pot realiza o schimbare lină și rapidă, care scurtează timpul de încărcare și descărcare, sporesc eficiența tăierii și reduc intensitatea muncii.

Închidere: Capacul complet închis poate proteja maxim siguranța personală și poate reduce poluarea cu praf.

4) Sistemul de transmisie

Mașina-uneltă adoptă o structură de antrenare dublă tip portal și un pat de mașină-unelte cu amortizare ridicată, cu o rigiditate bună, care poate suferi viteză și accelerație mare, sistem servo și sistem de antrenare AC importat, transmisie cu angrenaje și cremaliere importate, șină de ghidare liniară pentru ghidare, pentru a asigura viteza, precizie ridicată și fiabilitate ridicată a mașinii.

5) Sistem de control

Sistemul de tăiere cu laser cu fibre include procesul de tăiere cu laser, funcția normală de aranjare a stocului și controlul procesării cu laser. Are în principal proces de desen, setare parametri, editare a procesului de tăiere definit de utilizator, aspect al stocului, planificare a rutei, simulare și control de tăiere. Puterea de tăiere poate fi ajustată cu viteza de tăiere. Viteza individuală de tragere și extragere ar putea fi setată. De asemenea, are o bibliotecă de procesare a materialelor, care ar putea salva toți parametrii de proces pentru același material.

6) Sistem de indicare a luminii roșii

Lumina roșie coaxială este utilizată ca indicator pentru a face mai simplă reglarea sistemului optic și mai precisă pentru a stabili punctul de lucru.

7) Sistem de răcire

Sistemul de racire cu apa este echipat si temperatura poate fi indicata. Sistemul de răcire cu apă va începe să funcționeze automat când temperatura este mai mare decât valoarea prestabilită și va înceta să funcționeze automat când temperatura este sub valoarea prestabilită.

8) Ventilator de evacuare

Suflanta centrifugă îndepărtează praful pentru a menține un mediu de lucru bun și pentru a reduce daunele aduse siguranței personalului și echipamentului.

9) Clemă rotativă

Clema rotativa poate sustine teava rotunda Ф25mm-Ф160mm, teava patrata 25mmx25mm-100mmx 100mm (diagonala 30mm-160mm), cu grosimea 3mm, lungimea 6000mm. Dispozitivul de susținere a materialului poate fi menținut stabil pentru o lungă perioadă de timp pentru a funcționa.

Putere de ieșire cu laser | 2000w |

Lungimea de undă laser | 1070nm |

Mediu laser | Fibră de sticlă cu element rata-pământ |

Calitatea fasciculului laser | <0.373mrad |

Lățimea minimă a fasciculului | ≤0.125mm |

Raza maximă pentru axa X | 3000mm |

Interval maxim pentru axa Y | 1500mm |

Interval maxim pentru axa Z | 250 mm |

Precizie axială | ≤±0,05 mm/m |

Repetă precizie | ≤±0,03mm/m |

Dimensiune maximă pentru tăiere (axa XY) | 3000mmx1500mm |

Grosimea maximă de tăiere a oțelului carbon | 16 mm (grosime optimă 0,5--12 mm) |

Grosimea maximă de tăiere din oțel inoxidabil | 8 mm (grosime optimă 0,5--7 mm) |

Dimensiunea maximă a tăierii țevilor metalice | teava rotunda Ф160mm |

teava patrata 100mmx100mm (diagonala 30mm-160mm) | |

grosime 3mm, lungime 6000mm | |

Alimentare electrică | 380V / 50HZ |

Mașină de tăiat cu fibre laser avantaje:

1. Calitate excelentă a fasciculului de lumină: fațetă de focalizare mică, linie de tăiere fină, eficiență ridicată de lucru, cea mai bună calitate de procesare.

2. Viteză mare de tăiere: de 2 ori de către mașina de tăiat cu laser co2 cu aceeași putere.

3. Stabilitate ridicată: adoptați sursa laser din fibră importată de top cu proformanță stabilă, durata de viață a pieselor cheie ar putea fi 100.000 ore.

4. Eficiență ridicată a conversiei fotoelectrice: mașina de tăiat cu laser cu fibre este de 3 ori prin mașina de tăiat cu laser CO2, eficiența energetică și protecția mediului.

5. Cost redus de utilizare: mașina de tăiat cu laser cu fibra consumul este de numai 20-30% din mașina de tăiat cu CO2 cu aceeași putere.

6. Cost redus de întreținere: fără gaz de lucru pentru sursa de laser; fără lentile reflectorizante pentru transmiterea fibrelor.

7. Funcționare convenabilă: nu este necesar să reglați calea optică cu transmiterea fibrelor.

8. Efecte optice moi puternice: volum și structură compacte, flexibilitate ușor de utilizat.

9. Adoptați structura dublă de conducere Gantry, patul de mașini-unelte cu amortizare ridicată pentru o viteză mai mare și accelerare.

10. Acest model adoptă driverul de serviciu de curent alternativ importat și sistemul de transmisie importat, structura în mișcare a mașinii-unelte adoptă angrenajul și transmisia de creștere importate, linie de ghidare liniară pentru ghidare, asigurând viteza mare, precizia ridicată și fiabilitatea ridicată a echipamentului.

11. Rack și ghid adoptă un dispozitiv de protecție complet închis, care previne mișcarea de frecare fără ulei și poluarea prafului, îmbunătățește utilizarea duratei de transmisie și asigură precizia mișcării mașinii-unelte.

12. Sistem de control profesional cu mașină de tăiere cu laser, funcționare computer pentru o tăiere precisă și operare convenabilă.

Cerință de utilitate

Utilizatorul trebuie să asigure un mediu bun pentru echipament, cum ar fi podea nivelată pentru amplasarea echipamentului fără mișcare puternică, mediu curat și uscat, fără praf, 5-350C pentru funcționarea echipamentului. Sursa de alimentare trebuie furnizată: alimentare cu trei fraze și cinci linii 380V/50HZ. Utilizatorul trebuie să pregătească compresor de aer (mai mult de 0,6 metri pătrați pe minut pentru deplasarea aerului, mai mult de 1,0Mpa pentru presiunea aerului), hidrogen, azot și apă distilată pentru utilizarea de răcire (aproximativ 70L).